* Regardless of whether you buy our products, as long as you have questions related industries, we will sincerely to answer your questions*

Bluestone Crusher Hammer crusher is often used for bluestone crushing. The equipment is mainly developed and produced according to the characteristics of bluestone..

More +

The difference between 69 jaw crusher and 75 jaw crusher..

More +

Lime is a chemical material with calcium oxide as the main component. It is generally made of limestone, dolomite, etc. as raw materials through high temperature calcination. Lime is widely used, such as in civil engineering, medicine, etc..

More +

After crushing and processing, river pebble can be made into different sizes of sand and gravel, which is widely used in infrastructure projects. It has the characteristics of low mining cost and high application value, and is favored by many people..

More +

The stone crusher in the stone factory has played a major role in the development of the infrastructure in recent years. It processes different specifications of stones and machine-made sand, and the price of the equipment is transparent..

More +

The core parts of the pulverizer are grinding rollers, grinding rings, and assemblies. At the same time, these parts are also wearing parts. If you do not pay attention to the maintenance, it will lead to serious consequences..

More +

Ultrafine vertical mill grinding bentonite processBentonite has water swelling, cohesion, adsorption, lubricity, catalytic activity, thixotropy, plasticity and cation exchange properties. According to the type, content and crystalline chemical properties.

More +

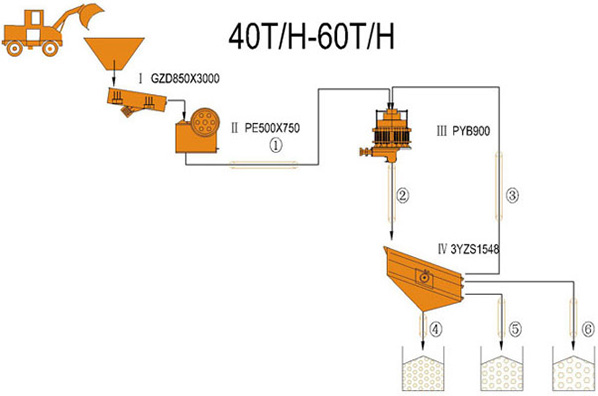

Depending on the hardness of the mine raw materials, the model configuration will vary greatly when selecting crushers. The sand and gravel production line is a special production line for producing sand and stones for construction, highway, railway and o.

More +

The configuration of the granite processing production line will be briefly introduced, and it is also suitable for materials that are difficult to crush or costly to break, such as basalt, diabase, andesite..

More +

How to reduce the wear of impact crusher blow bar? Due to the large crushing ratio of the impact crusher, the wear of its wearing parts is particularly prominent, even bringing frequent downtime maintenance. Among them, the blow bar is the main operation.

More +