Limestone has a Platts hardness between 3-5 and a bulk density of 1.2-1.5t/m³, which is medium-hardness but relatively soft. Therefore, the limestone is easy to be crushed and it is generally crushed by jaw crusher, impact crusher, etc..

The limestone are fed into the vibrating feeder by the dump truck. The vibrating feeder evenly transport the materials to jaw crusher for primary crush, then the belt conveyor carry the material to impact crusher for secondary crush. Finally, the material will be sieved by the circular vibrating screen. The final product will be conveyed to the product area by belt conveyor. The oversize materials will be transported to the impact crusher for re-crushing, and the final product will be conveyed to the product area by belt conveyor. The jaw crusher&impact crusher of the limestone crushing process is the most conventional.

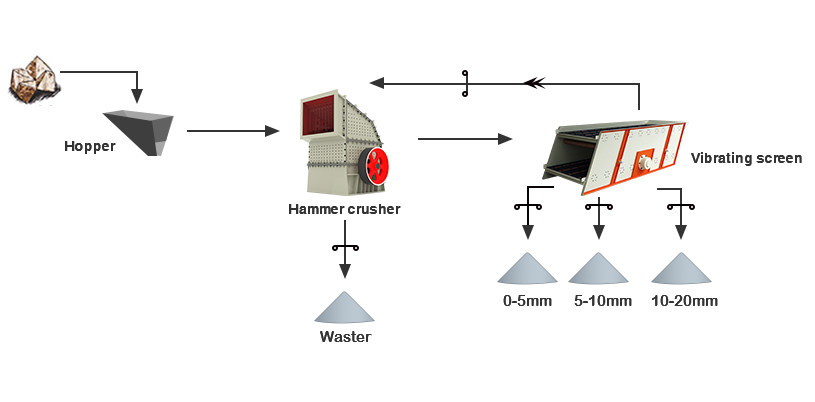

The vibrating feeder evenly deliver the large limestone to the hammer crusher for crushing. The belt conveyor transport the limestone materials to the circular vibrating screen for sieving. The materials with required size are transported to the final product pile by the belt conveyor, and the oversize materials return to the hammer crusher for secondary crush that formed a closed circuit for re-crushing. The above configuration needs the lowest investment, the simplest maintenance and the minimal production cost. The heavy hammer crusher, combining the characteristics of the traditional single-stage hammer crusher and the impact crusher, can be used for multi-purpose. It can be used for primary crush and the secondary crush. Besides, it can crush raw materials into required finished produsts at one crush, which can decrease the investment by 30-40%.

*We will provide you with the most suitble producets*

*We Promise to reply within 24 hours.*