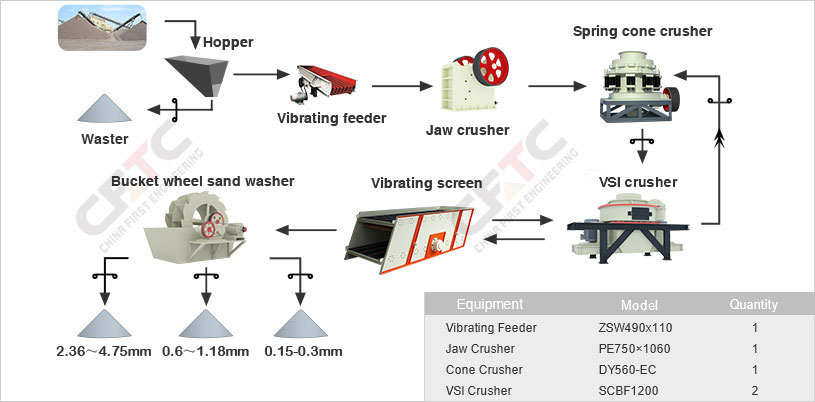

Large stone are evenly fed into the jaw crusher by vibrating feeder for primary crushing. The crushed coarse stone are conveyed to the spring cone crusher by the belt conveyor for secondary crushing, then the fine material is transported to the vibrating.

Large stone are evenly fed into the jaw crusher by vibrating feeder for primary crushing. The crushed coarse stone are conveyed to the spring cone crusher by the belt conveyor for secondary crushing, then the fine material is transported to the vibrating screen by belt conveyor for screening. After screening, the particle size of material less than 40mm is conveyed to the VSI crusher for sand making. The material with size larger than 40mm will be conveyed back to spring cone crusher for re-crushing to achieve a closed circuit. The artificial sand is transported to the vibrating screen for screening, then several different specifications of artificial sand can be get. The particle size of artificial sand less than 0.5mm is conveyed to the sand washing machine by the belt conveyor for washing, which can washed out dirt and debri to get high-quality final sand. Oversized material will be returned to the VSI crusher for re-crushing until all the materials are turned into sand.

*We will provide you with the most suitble producets*

*We Promise to reply within 24 hours.*