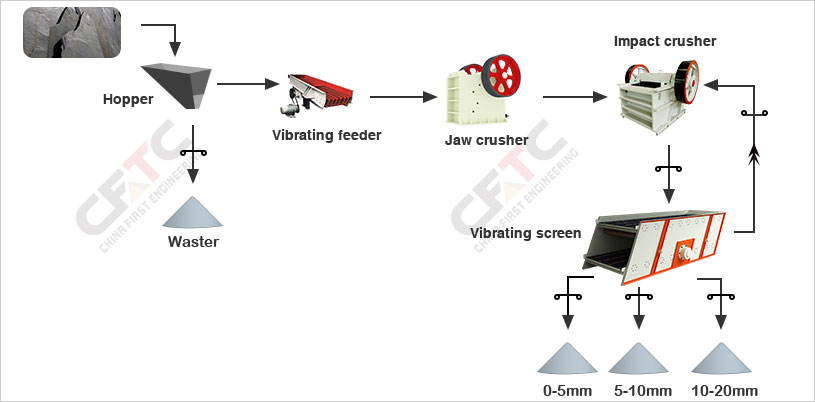

The shale is easily cracked into fragments when struck by a hard object. The commonly used shale crushing processes are as follows: jaw crusher (primary crush) →impact crusher or fine jaw crusher (secondary crush) → vibrating screen (screening process)..

Basalt generally applys the process of jaw crusher & cone crusher(the flow chart on the right). The basalt are put into vibrating feeder by the dump truck. The vibrating feeder evenly transport the basalt materials to the jaw crusher for primary crush. Then coarse materials are transported to the cone crusher by belt conveyor for secondary crush. Finally, the materials will be sieved by the vibrating screen, and the qualified particles will be conveyed to the product area. The oversize materials will be delivered back to the cone crusher for re-crushing. The crushing forms of jaw crusher & cone crusher can reduce the equipment abrasion, increase wear life, improve the continuity of work and reduce operating costs.

The materials were blasted from the mountain, and it was sent to the vibrating feeder by hopper. The vibrating feeder evenly sent the materials into jaw crusher for primary crush, then the materials were sent to a group of double jaw crushers by the belt conveyor for secondary crush. Through the crushing of the double jaw crushers , the materials are almost qualified products. Finally, the materials will be sieved by the vibrating screen, and the final product with high quality will be conveyed to the product area by belt conveyor.

*We will provide you with the most suitble producets*

*We Promise to reply within 24 hours.*