With high electrical conductivity and good thermal conductivity, molybdenum and its alloys have extensive applications and good prospects in metallurgy, agriculture, electrical, chemical, environmental protection, aerospace department, etc..

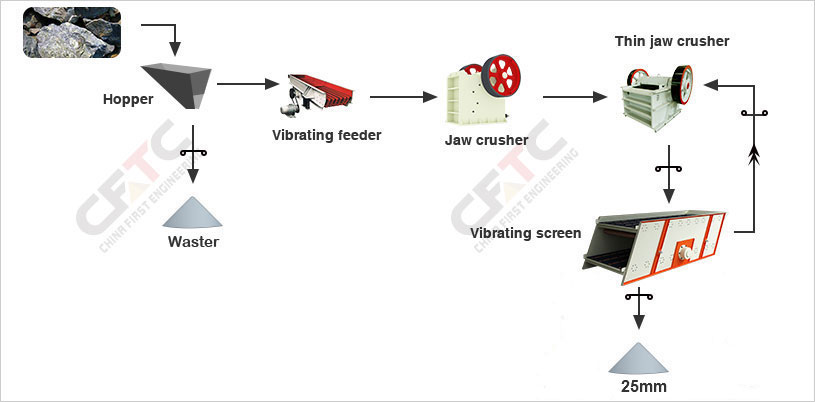

The crushing of molybdenum ore apply the two-stage crushing process of jaw crusher & fine jaw crusher. The molybdenum ore are transport to the vibrating feeder by dumper, then it is fed into the jaw crusher for primary crush. After primary crush, the crushed coarse molybdenum is put into the fine jaw crusher by the belt conveyor for secondary crush. Finally, the materials will be sieved by the circular vibrating screen. The final product will be conveyed to the product area by belt conveyor, and the oversize materials return to the fine jaw crusher for re-crushing.

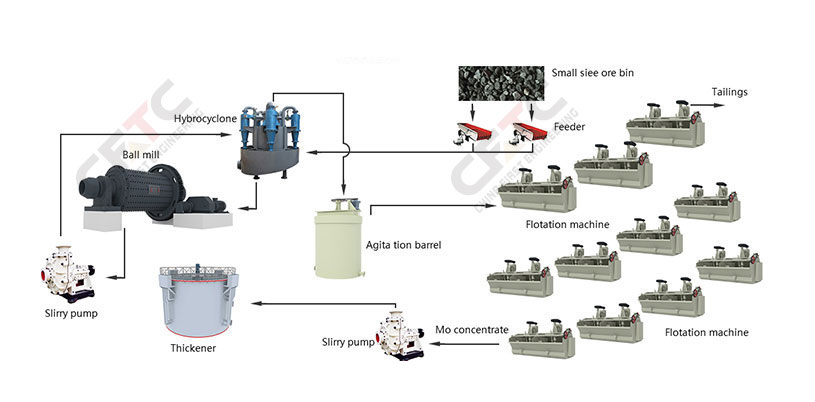

The final products are conveyed to the ball mill by belt conveyor for grinding, then it is washed by spiral sand washer. The washed materials are put into the mixing tank for mixing, and oversize materials are sent back to the ball mill for re-grinding. The qualified materials are put into flotation cell with suitable flotation agent for a period of flotation. Then the materials are sent to the thickener for primary concentration and precipitation. Finally, the materials are put into dryer for dehydrating, and the tin concentrate can be obtained.

*We will provide you with the most suitble producets*

*We Promise to reply within 24 hours.*