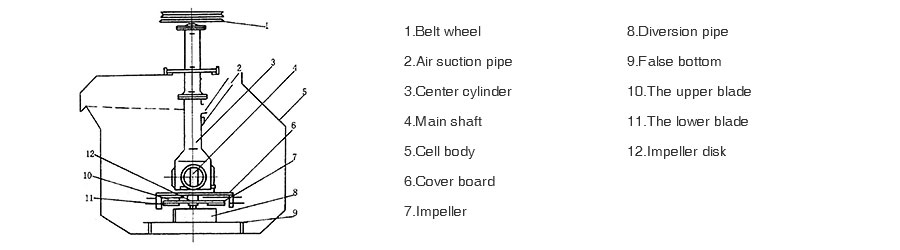

SF flotation machine is a mining flotation machine which can be widely used in beneficiation of non-ferrous metals, ferrous metals and non-metallic minerals, and is suitable for roughing and scavenging in large and medium-sized flotation plant. This kind of flotation machine adopts the forward tilting tank with novel structure and double-sided blade water wheel and is equipped with diversion pipe and false bottom device. Therefore, the slurry in the tank can conduct the upper and lower circulation flow according to fixed flow method, which is conducive to flotation of coarse particle minerals. Moreover, this kind of flotation machine can intake air and slurry. Therefore, no foam pump is required.

1.Large suction and low power consumption.

2.Long service life of wearing parts.

3.Each tank has the function of air suction, slurry suction and flotation, which can form the flotation circuit without auxiliary equipment. Moreover, the horizontal configuration is easy to change the process.

4.The reasonable slurry can minimize the coarse sand precipitation, which is conducive to flotation of coarse particle minerals.

5.This kind of flotation machine is equipped with automatic control device, which is easy to adjust slurry surface.

6.Impeller is equipped with upper and lower tilt back blades. The upper blade produces the upper the circulation of slurry; the lower blades produces the lower circulation of slurry.

7.Mechanical agitation, self-priming, self-priming slurry.

When the impeller rotates, slurry in the upper and lower impeller cavity is thrown to the surrounding under the action of centrifugal force generated by upper and lower blades. Therefore, negative pressure zone is formed in the upper and lower impeller cavity. At the same time, slurry in the upper part of the cover plate is sucked into the upper impeller cavity through circulation holes, which forms the upper circulation of slurry. When the lower blade throws the slurry to the surrounding, slurry in the lower part of the cover plate flows toward the center, which forms the lower circulation of slurry. Through suction of air intake pipe and the center cylinder, the air is mixed with the slurry in the upper impeller cavity, which forms a large number of small bubbles. Through steady flow of the cover plate, the mixture is evenly dispersed in the tank and forms mineralized bubbles. Finally, which float to the foam layer and are scraped by the scraper to form the foam product.

Please strictly refer to the product technical parameters for work. specifications are subject to change without notice. Please refer to the actual data of machine.

| Model | Effective Volume (m³) | Production capacity(m³/min) | Principal axis | Scraper | Overall dimensions(mm) | Weight(t) | ||

| Power(kW) | speed(r/min) | Power(kW) | speed(r/min) | |||||

| SF-0.37 | 0.37 | 0.2-0.4 | 1.5 | 386 | 17 | 0.55 | 700*700*750 | 0.47 |

| SF-0.7 | 0.7 | 0.3-0.9 | 3 | 400 | 16 | 0.55 | 820*900*950 | 0.81 |

| SF-1.2 | 1.2 | 0.6-1.2 | 5.5 | 340 | 16 | 1.1 | 1100*1100*1100 | 1.37 |

| SF-2 | 2 | 0.8-2 | 7.5 | 340 | 16 | 1.1 | 1400*1400*1150 | 1.75 |

| SF-2.8 | 2.8 | 1.0-3.0 | 11 | 268 | 16 | 1.5 | 1700*1600*1150 | 2.13 |

| SF-4 | 4 | 2.0-4.0 | 15 | 220 | 16 | 1.5 | 1850*2050*1200 | 2.58 |

| SF-8 | 8 | 4.0-8.0 | 30 | 191 | 16 | 1.5 | 2200*2900*1400 | 4.12 |

| SF-10 | 10 | 5.0-10 | 30 | 191 | 16 | 1.5 | 2200*2900*1700 | 4.48 |

| SF-20 | 10 | 5.0-20 | 30x2 | 191 | 16 | 1.5 | 2850*3800*200 | 9.82 |

Note:The capacity may vary with different materials and feeding sizes. Technical parameters are subject to change without notice.

CFTC is one of the most reliable Flotation Cell manufacturers in China with many years of experience in Flotation Cell production . We can supply a complete set of Flotation Cell with highest quality. Our Flotation Cell have been exported to Kenya ,Ethiopia, Zambia, Tanzania, Saudi Arabia,Sri Lanka, Egypt ,Pakistan ,Vietnam ,Indonesia, the Philippines, SouthAfrica and other countries . If you have this need , please contact us or send email to sales@china-cfc.cc

*The Similar product for you choose*

*We Promise to reply within 24 hours.*