Clinker refers to clay, pre-fired ceramic materials that has been burned too much in the kiln. Generally, gypsum is also added to the molding material formula for increasing strength, and increasing hardness when fired. Clinker is also used in the manufac.

The materials were blasted from the mountain, and it was sent to the vibrating feeder by hopper. The vibrating feeder evenly sent the materials into jaw crusher for primary crush, then the materials were sent to the impact crusher by the belt conveyor for secondary crush. Finally, the materials will be sieved by the vibrating screen that the oversize materials will be sent back to the impact crusher for re-crushing, and the final product with high quality will be conveyed to the product area by belt conveyor.

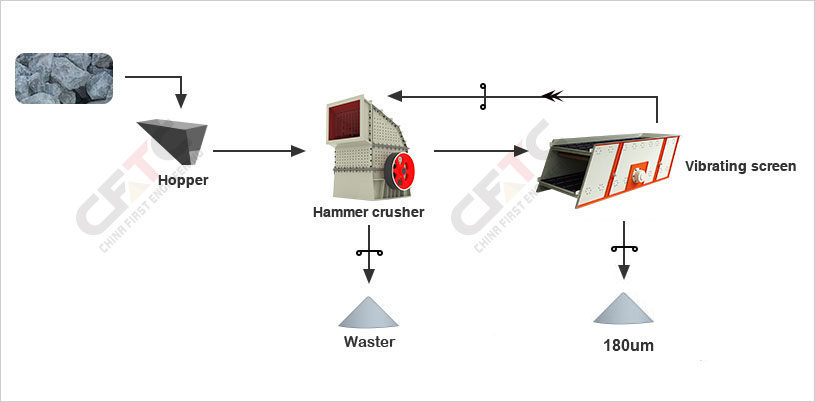

The hummer crusher is single-stage crushing design, which adopts hammer crusher to instead of 2 machines (jaw crusher + impact crusher) that mentained above with much lower cost. The capacity of this production line is up to 1000tph with low power consumption and high quality of final products.

*We will provide you with the most suitble producets*

*We Promise to reply within 24 hours.*