The energy saving ball mill is a key equipment for grinding after crushing process. And its grinding media is a number of steel balls filled in the barrel. The energy saving ball mill is widely used in production industries such as cement, refractory materials, chemical fertilizers, glass ceramics, as well as mineral processing, building materials and chemical industries,etc.

1. Easy to operate and maintain with simple structure

2. Easy to adjust the fineness of the material with higher reduction ratio

3. Saving 20-30% energy with large double row self-aligning roller bearing with low friction force

4. Continuously grinding a variety of materials to meet the needs of large-scale manufacturers

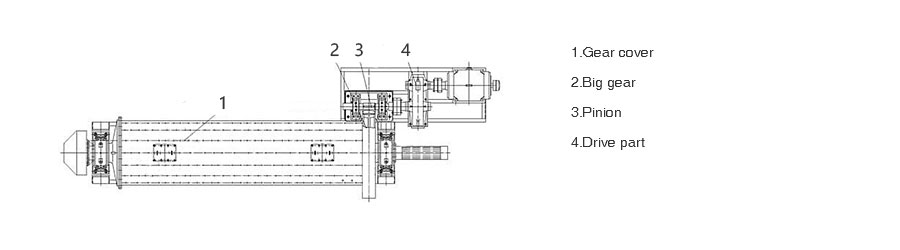

The energy saving ball mill is a horizontal rotating device. It has two chambers and is driven by the outer gear. The material is evenly fed into the first chamber throughthe feeding inlet. There is a ladder liner or a ripple liner in the first grinding chamber that contains steel balls of different specifications. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height, which can impact and grind the materials when the balls fall. After coarse grinding, the material is transported to the second chamber for further grinding, after which the ground material is discharged. And the whole grinding process is completed.

Please strictly refer to the product technical parameters for work. specifications are subject to change without notice. Please refer to the actual data of machine.

| Model | Cylinder speed(r/min) | Ball load(t) | Feed size(mm) | Discharge size(mm) | Capacity(tph) | Weight of main engine (kW) | Weight(t) |

| 1200x2400 | 36 | 3 | ≤25 | 0.074-0.6 | 1.4-2.8 | 30 | 11.4 |

| 1200x3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-3 | 37 | 12.1 |

| 1200x4500 | 32.6 | 5 | ≤25 | 0.074-0.4 | 1.83-3.9 | 55 | 13.1 |

| 1500x4500 | 27 | 11 | ≤25 | 0.074-0.4 | 4.8-11 | 90-110 | 199 |

| 1500x5700 | 28 | 12 | ≤25 | 0.074-0.4 | 5--16 | 130 | 23.4 |

| 1830x2400 | 25.4 | 10 | ≤25 | 0.074-0.4 | 4--10 | 130 | 23.7 |

| 1830x3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4.5-10.5 | 130 | 26.6 |

| 1830x4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 68-11.5 | 155 | 30.4 |

| 1830x6000 | 24.1 | 21 | ≤25 | 0.074-0.4 | 7--12 | 210 | 32.3 |

| 1830x7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.8-13.8 | 245 | 34.2 |

| 2100x3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 5.8-14 | 155 | 32.3 |

| 2100x4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 9.5-32 | 245 | 40 |

| 2100x6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 50.3 |

| 2100x7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 51.3 |

| 2100x7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 53.2 |

| 2400x3000 | 21 | 23 | ≤25 | 0.074-0.4 | 7.8-18 | 245 | 51.3 |

| 2400x4500 | 21 | 30 | ≤25 | 0.074-0.4 | 13.7-28 | 320 | 64.7 |

| 2700x4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 15-28 | 400 | 89 |

| 2700x4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 16.5-36 | 430 | 97 |

| 3200x4500 | 18 | 65 | ≤25 | 0.074-0.4 | 24-49 | 800 | 130.5 |

| 3600x4500 | 17.8 | 88 | ≤25 | 0.074-0.4 | 29-65 | 1250 | 165 |

Note:The capacity may vary with different materials and feeding sizes. Technical parameters are subject to change without notice.

CFTC is one of the most reliable Energy Saving Ball Mill manufacturers in China with many years of experience in Energy Saving Ball Mill production . We can supply a complete set of Energy Saving Ball Mill with highest quality. Our Energy Saving Ball Mill have been exported to Kenya ,Ethiopia, Zambia, Tanzania, Saudi Arabia,Sri Lanka, Egypt ,Pakistan ,Vietnam ,Indonesia, the Philippines, SouthAfrica and other countries . If you have this need , please contact us or send email to sales@china-cfc.cc

*The Similar product for you choose*

*We Promise to reply within 24 hours.*