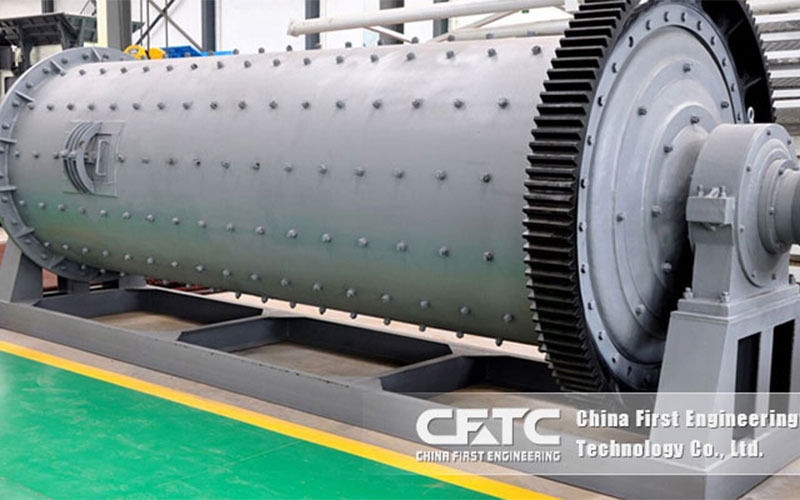

There are two types of aluminum ash and aluminum slag seperators in terms of mechanical types. The first is ball mill, which is also a traditional machine used in the early days. However, ball mills have many disadvantages in traditional processes, such as cumbersome procedures, large dust, and loud noise. It consumes a lot of manpower and increases the cost of aluminum ash treatment and environmental pollution.

The second type is the new type of aluminum gray Raymond seperator. Its shape is very similar to that of Raymond mill. Most people can’t tell the difference. The separator is actually an upgraded product of the Raymond mill.

What is the effect of using Raymond mill to grind 400 mesh aluminum ash with aluminum ash and aluminum slag seperator?

Raymond mill is a relatively popular aluminum ash separator in the market at present. It can grind powder and winnow at the same time, replacing the screening process of ball mill, and Raymond mill is equipped with a dust collector, which has low noise and dust. The power consumption is small, and the equipment investment is small. Small footprint, no need to lay foundations, etc., has become the mainstream equipment in the current aluminum ash and aluminum slag treatment market. If the 400-mesh aluminum ash is processed and used for water purifier powder, slag remover, and mortar powder, it can be applied directly after being processed by a Raymond mill.

*We will provide you with the most suitble producets*

*Wo Promise to reply within 24 hours.*