Single cylinder hydraulic cone crusher integrates mechanical, hydraulic, electrical, automation, intelligent control and other technologies in one, and it is widely used in non-metallic ore, cement, sand and stone, metallurgy and other industries for medium crushing, fine crushing and super fine crushing. The single cylinder hydraulic cone crusher has the features of high crushing efficiency, low production cost, convenient maintenance and adjustment, and excellent product particle size.The single cylinder hydraulic cone crusher is generally used in metallurgy, construction, road construction, chemical and silicate industries, and it can crush various ores and rocks with medium hardness or higher.

1.Automatic control and stable operation;

2.High crushing efficiency and good product shape;

3.Optimized structure and easy operation;

4.Hydraulic technology overload protection and hydraulic adjustment discharge port; 5.Safe and reliable thin oil lubrication station extending crusher service life

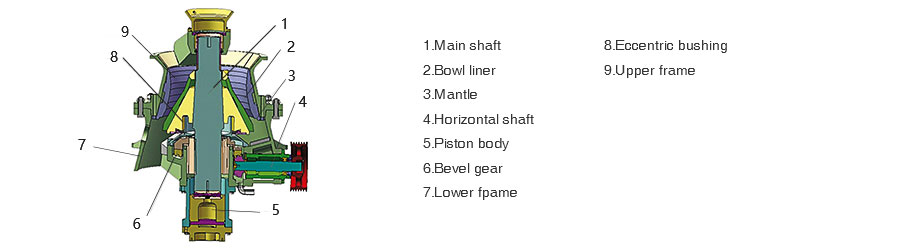

When the single cylinder cone crusher is working, the horizontal shaft is driven by the motor to start rotating, and then the horizontal shaft drives the eccentric sleeve to rotate through the gear. Finally, the moving cone part is driven by the eccentric sleeve to make a circular swing to crush stones continuously, which has good crushing effect. When unbreakable objects such as metal blocks fall into the crusher, the moving cone is supported by the hydraulic piston at the bottom, which plays the role of discharge port adjustment and over-iron protection. Besides, the hydraulic piston will up and down repeatedly to eliminate mine blockage.

Please strictly refer to the product technical parameters for work. specifications are subject to change without notice. Please refer to the actual data of machine.

| Model | Stroke (mm) | Power (kW) |

Weight (t) |

Discharge opening (mm) Capacity (tph) | |||||

| 8mm | 10mm | 15mm | 20mm | 25mm | 30mm | ||||

| HPS100 | 16 | 90 | 5.7 | 40-50 | 40-50 | 60-70 | Sep-80 | 85-95 | |

| 20 | 50-55 | 50-55 | 70-80 | 9-105 | |||||

| 25 | 56-65 | 75-90 | 105-120 | ||||||

| Model | Stroke (mm) | Power (kW) |

Weight (t) |

Discharge opening (mm) Capacity (tph) | |||||

| 20mm | 25mm | 30mm | 35mm | 40mm | 45mm | ||||

| HPS100S | 16 | 90 | 7.35 | 80-90 | 105-115 | 120-130 | 135-145 | 145-165 | 155-175 |

| 20 | 145-155 | 160-180 | 170-200 | 185-215 | |||||

| 25 | 185-195 | 200-220 | 210-230 | ||||||

| Model | Stroke (mm) | Power (kW) |

Weight (t) |

Discharge opening (mm) Capacity (tph) | ||||||

| 8mm | 12mm | 16mm | 20mm | 25mm | 30mm | 35mm | ||||

| HPS100S | 16 | 90 | 7.35 | 65-75 | 75-90 | 85-105 | 100-125 | 135-150 | 160-175 | 170-190 |

| 20 | 90-110 | 110-130 | 125-155 | 160-180 | 185-210 | |||||

| Model | Type of cavity | Max.feeding size | Power(kW) | Weight(t) | Discharge opening (mm) Capacity (tph) | |||||||||

| 8mm | 10mm | 13mm | 16mm | 19mm | 22mm | 25mm | 32mm | 38mm | 44mm | |||||

| HPS440 | (EC) | 215 | 220 | 14.3 | 101 | 114-200 | 122-276 | 131-294 | 139-313 | 159-357 | 175-395 | 192-384 | ||

| (C) | 175 | 97-122 | 109-218 | 117-292 | 125-312 | 133-332 | 151-378 | 167-335 | 183-229 | |||||

| (MC) | 140 | 117-187 | 105-262 | 113-282 | 120-301 | 128-320 | 146-328 | 161-242 | ||||||

| (M) | 110 | 124 | 126-278 | 136-298 | 145-318 | 154-339 | 175-281 | |||||||

| (MF) | 85 | 114 | 227 | 134-245 | 144-263 | 153-281 | 163-299 | 186-248 | ||||||

| (F) | 70 | 90-135 | 96-176 | 104-191 | 112-206 | 120-221 | 129-236 | 137-251 | 156-208 | |||||

| (EF) | 38 | 100-125 80% of 6mm-7.5mm 100-125 in 80% < 6mm-7.5mm | ||||||||||||

| Model | Type of cavity | Max.feeding size | Power(kW) | Weight(t) | Discharge opening (mm) Capacity (tph) | |||||||||

| 25mm | 29mm | 32mm | 35mm | 38mm | 41mm | 44mm | 48mm | 51mm | 54mm | |||||

| HPS440S | (EC) | 215 | 220 | 14.3 | 267 | 282-353 | 298-446 | 313-563 | 334-601 | 390-524 | 365-456 | |||

| (C) | 175 | 225 | 239-299 | 254-381 | 269-484 | 284-511 | 298-448 | 318-398 | 333 | |||||

| (MC) | 140 | 195 | 214-267 | 228-342 | 242-435 | 256-461 | 270-486 | 284-426 | 303-378 | 317 | ||||

Note:The capacity may vary with different materials and feeding sizes. Technical parameters are subject to change without notice.

CFTC is one of the most reliable Single Cylinder Cone Crusher manufacturers in China with many years of experience in Single Cylinder Cone Crusher production . We can supply a complete set of Stone Crusher with highest quality. Our products have been exported to Kenya ,Ethiopia, Zambia, Tanzania, Saudi Arabia,Sri Lanka, Egypt ,Pakistan ,Vietnam ,Indonesia, the Philippines, SouthAfrica and other countries . If you have this need or want to get the Single Cylinder Cone Crusher price , please contact us or send email to sales@china-cfc.cc

*The Similar product for you choose*

*We Promise to reply within 24 hours.*