The hydrocyclone is a device that uses a centrifugal inertia force to grade materials in a swirling flow. The use of a certain pressure to the slurry along the tangential direction of the feed, so that rotation, the slurry in the centrifugal force under the action to accelerate the deposition of the inner part of the cyclone to achieve the purpose of classification. The whirlpool feeding method is currently used directly to the sand pump feed.

1.Hydrocyclone: graded cyclone and desliming cyclone.

2.Graded cyclone can classify particles of 800-74 microns (43 microns). This kind of cyclone has higher ore feeding solid mass fraction, larger ore feeding pressure and thicker cylinder diameter;

3.Desliming cyclone can remove fine particles of 74 -5 microns (or 43-5 microns). This kind of cyclone has lower ore feeding solid mass friction, smaller ore feeding pressure and thinner cylinder diameter.

4.Advantages: simple structure, small footprint & high productivity.

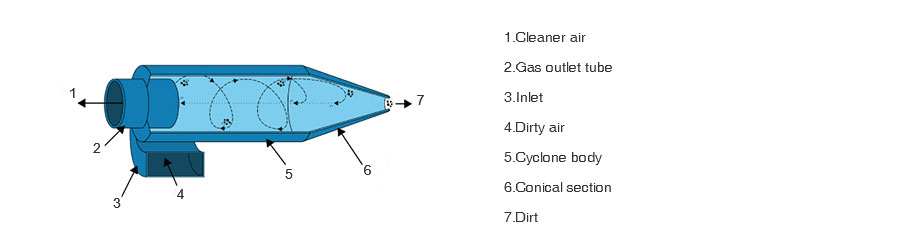

Under the pressure (0.04-0.35MPa), the slurry goes into the cyclone along the tangential direction through feeding pipe, which forms high-speed rotary flow in the interior of the cyclone and produces great centrifugal force. At the center of the cyclone, rotary speed of slurry and centrifugal force reach the maximum value. As a result of the expansion of the slurry to the surroundings, a low pressure band is formed around the central axis. The air inhaled through the sinker mouth forms low pressure air column in the central axis. In addition to the tangential rotation movement, the slurry in the cyclone also has radial movement toward the center. Moreover, the slurry close to the center also has the upward movement along the axial direction while the peripheral slurry mainly makes downward movement toward the sinker mouth along the axial direction where there exists a zero point that the slurry will change the movement direction. The points are connected in the space to form an approximately conical surface, which becomes the zero velocity envelope surface. By means of the larger centrifugal inertial force, the medium and coarse particles in the slurry move outward and remain at the zero velocity envelope surface. With the downward movement of peripheral slurry, the medium and coarse particle minerals are finally discharged by the sinker mouth. The fine particles have slower centrifugal sedimentation speed, which are carried by the upward vortex and finally discharged by overflow pipe.

Please strictly refer to the product technical parameters for work. specifications are subject to change without notice. Please refer to the actual data of machine.

| Model | Diameter(mm) | Height(mm) | Feeding pressure(Mpa) | Separation size(μm) | Weight(t) |

| FX-75 | 75 | 472.5 | 0.1-0.5 | 20-60 | 4 |

| FX-100 | 100 | 499 | 0.05-0.4 | 20-60 | 8 |

| FX-125 | 125 | 590 | 0.05-0.4 | 25-65 | 10 |

| FX-150 | 150 | 786 | 0.05-0.4 | 30-75 | 22 |

| FX-200 | 200 | 1114 | 0.05-0.4 | 40-100 | 36 |

| FX-250 | 250 | 1380 | 0.05-0.4 | 40-100 | 63 |

| FX-300 | 300 | 1490 | 0.03-0.4 | 50-150 | 88 |

| FX-350 | 350 | 1674 | 0.03-0.4 | 50-150 | 135 |

| FX-500 | 500 | 2280 | 0.03-0.4 | 74-200 | 416 |

| FX-660 | 660 | 2720 | 0.03-0.4 | 74-200 | 950 |

Note:The capacity may vary with different materials and feeding sizes. Technical parameters are subject to change without notice.

CFTC is one of the most reliable Hydrocyclone manufacturers in China with many years of experience in Hydrocyclone production . We can supply a complete set of Hydrocyclone with highest quality. Our Hydrocyclone have been exported to Kenya ,Ethiopia, Zambia, Tanzania, Saudi Arabia,Sri Lanka, Egypt ,Pakistan ,Vietnam ,Indonesia, the Philippines, SouthAfrica and other countries . If you have this need , please contact us or send email to sales@china-cfc.cc

*The Similar product for you choose*

*We Promise to reply within 24 hours.*