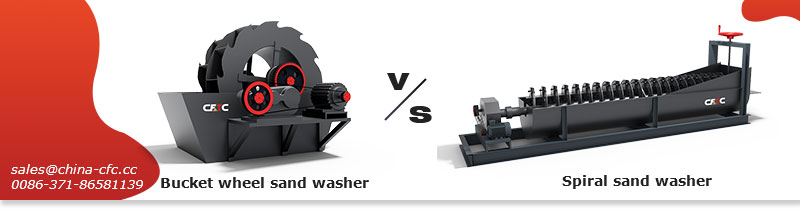

As one of basic machine in sand making production line, sand washer is widely used in sand and gravel, mining, building materials, transportation, chemical, water conservancy and hydropower, concrete mixing plants and other industries. Sand washer is divided into spiral sand washer and wheel bucket sand washer according to its structure and working principle.

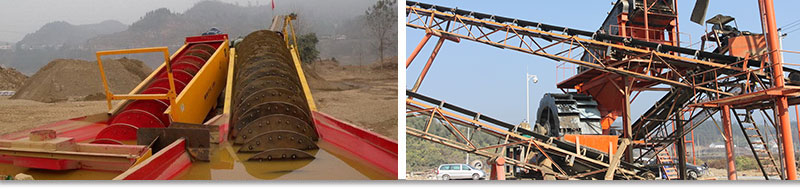

Spiral sand washer is featured by simple structure, stable operation, high cleaning, large capacity, etc. And it is popular in construction sites, sand and gravel plants, glass factories, power station stations, concrete prefabricated stones, and electric fields.

When operating, the motor drives the impeller slowly rotating through the V-belt and reducer. The sand is put into the washing tank through the feeding chute, and rolls over by the impellter driving. During the rolling, the friction between the sand particles strips the impurities, and breaks the vapor coatings around the particles in order to facilitate dehydration. Meanwhile, massive water is put into the washing tank to form a strong water stream to take the impurities and small percentage of foreign matters away immediately and discharge them from the overflow port. Click to learn more https://www.china-cfc.cc/product/sandmaking/spiralsandwasher.html

The bucket sand washer shows novel sealing structure, reliable transmission, reasonable structure, high capacity, low consumption, high cleaning and little sand loss. The transmission part of the bucket sand washer is isolated from water and sand, and the failure rate is much lower than that of the commonly used sand washers on the market. It is an ideal choice for upgrading the domestic sand washing industry.

When operating, the motor drives the impeller slowly rotating through the V-belt and reducer. The sand is put into the washing tank through the feeding chute, and rolls over by the impellter driving. During the rolling, the friction between the sand particles strips the impurities, and breaks the vapor coatings around the particles in order to facilitate dehydration. Meanwhile, massive water is put into the washing tank to form a strong water stream to take the impurities and small percentage of foreign matters away immediately and discharge them from the overflow port. The clean sand is taken by the impeller, and finally puts into the discharge groove, finishing the whole washing process. Click to learn more https://www.china-cfc.cc/product/sandmaking/bucketwheelsandwasher.html

Therefore, the sand and gravel production plant should the sand washer according to the composition of the sand stone and the condition of the production site to achieve a good sand washing effect and improve the cleanliness of the sand stone.

*We will provide you with the most suitble producets*

*Wo Promise to reply within 24 hours.*