The medium of elliptical sphere is selected instead of spherical medium, and the ball adopts grooved annular lining plate, which effectively increases the contact surface between the ball and the material during operation, and the crushing and grinding capacity of the mill is greatly improved. The user can make the equipment perform continuous operation, with large output and high production efficiency, which can meet the needs of large-scale production.

The equipment adopts a special sealing system, which can effectively reduce the dust and noise during the operation, which not only reduces the physical injury to the operator, but also effectively avoids the noise and dust environment pollution during the operation.

The grinding energy consumption is highly matched with the drive of the equipment, and the energy consumption in the operation is low, which can save a lot of energy consumption expenses for users every year.

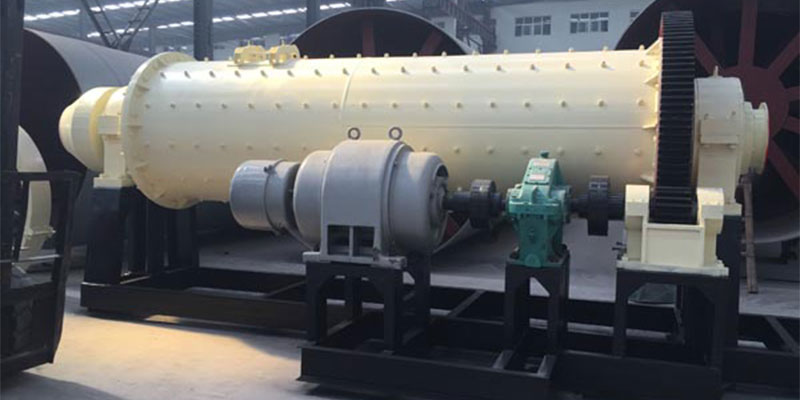

The structure design of the ball mill is not only beautiful, but also very reasonable, which is convenient for customers to operate and maintain in production. The length of the equipment is not less than 1.8m, which can effectively reduce the floor space of the equipment and facilitate the user's production movement.

The main bearing adopts the double row self-aligning stick bearing with larger diameter, the friction during operation is small, the equipment is more sturdy and durable, and the user's investment in equipment maintenance is low.

The price of the ball mills sold in the market is relatively affordable, especially the equipment produced by Klirick, which not only has an ultra-low price, but also the quality of the equipment and after-sales service are also very guaranteed, which solves the user's worries and makes the Users are more profitable.

*We will provide you with the most suitble producets*

*Wo Promise to reply within 24 hours.*