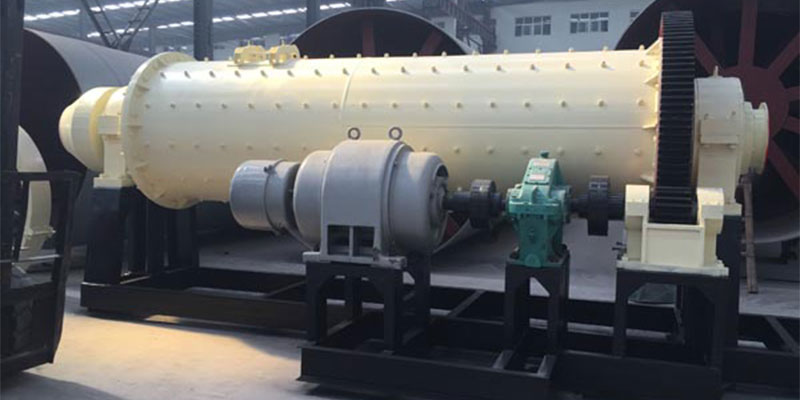

It is selected according to the particle size of the grinding material. The material is loaded into the barrel by the hollow shaft at the feed end of the ball mill. When the ball mill barrel rotates, the grinding body is attached to the barrel liner due to the action of inertia, centrifugal force and frictional force. It is taken away by the cylinder, and when it is brought to a certain height, it is thrown down due to its own gravity, and the falling grinding body crushes the material in the cylinder like a projectile.

The material enters the mill chamber spirally and evenly from the feeding device through the feeding hollow shaft. There are stepped lining plates or corrugated lining plates in the chamber, and various specifications of steel balls are installed inside. The rotation of the cylinder generates centrifugal force to bring the steel balls to a certain height. Falling, pounding and grinding the material. After the material reaches the rough grinding in the warehouse, it enters the second warehouse through the single-layer partition board. The warehouse is inlaid with a flat lining board and has steel balls to further grind the material. The powder is discharged through the discharge grate to complete the grinding operation.

During the rotation of the cylinder body, the grinding body also slips off. During the sliding process, the material is subjected to grinding action. In order to effectively utilize the grinding action, the grinding body cylinder is ground when the particle size of the material is generally 20 mesh. The material is divided into two sections by the partition board, that is, it becomes a double warehouse. When the material enters the warehouse, it is crushed by steel balls. When the material enters the second warehouse, the steel section grinds the material, and the ground and qualified materials are discharged from the hollow shaft at the discharge end. , When grinding materials with small feed particles, such as No. 2 sand slag, coarse fly ash, the barrel of the mill can be a single-silo mill without partitions, and the grinding body can also be made of steel.

The raw materials are fed into the hollow cylinder through the hollow journal for grinding, and the cylinder is equipped with grinding media of various diameters (steel balls, steel bars or gravel, etc. When the cylinder rotates at a certain speed around the horizontal axis, under the action of centrifugal force and frictional force, the medium and raw materials in the cylinder will leave the cylinder when the gravity of the cylinder is greater than the centrifugal force as the cylinder reaches a certain height. The inner wall is projected to fall or roll down, breaking the ore due to the force of the impact. At the same time, during the rotation of the mill, the sliding movement of the grinding media between each other also produces a grinding effect on the raw materials. The ground material is discharged through the hollow journal.

*We will provide you with the most suitble producets*

*Wo Promise to reply within 24 hours.*