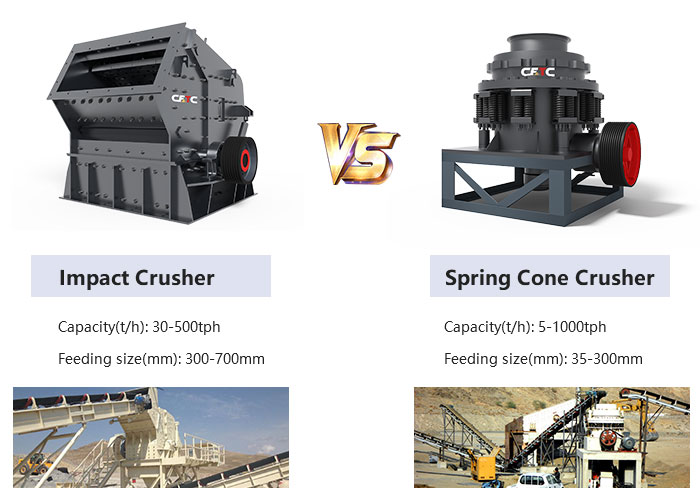

A complete stone crushing production line usually is composed of coarse crushing and medium and fine crushing. And the jaw crusher machine generally is used in the coarse crushing stage and cone crusher machine and impact crusher machine are commonly used in the medium and fine crushing stage. So there’s is a question that is the cone crushing machine or the impact crushing machine is more perfect for the medium and fine crushing stage. First of all, let see the differences between the two crushing machines:

Although cone crusher and impact crusher both are medium and fine crushing stage machine, their processing different hardness stones. Generally, the cone crusher machine is more suitable for breaking high hardness materials like granite, basalt, river stone, iron ore, gold ore and other metallic ores. While the impact crusher machine is suitable for crushing medium and low hardness materials, such as blue stone, limestone, etc.

The impact crusher crushes materials by impact force because the materials are crushed into particles by impacting between the blow bar and counter-attack board; while the cone crusher breaks materials by laminating crushing because the concave moves to the mantle again and again to squeeze materials between them. Therefore, impact crusher machine will have more heavy abrasion than cone crusher when crushing high hardness materials.

Compared with the impact crusher machine, cone crusher machine has advantages of low energy consumption, high yield and stable production, etc. So cone crusher is usually used in large scale and high output stone crushing production line.

Cone crusher machine has many crushing cavities including coarse, medium, fine and extreme fine cavities, so the cone crusher has finer discharging granularity than the impact crusher machine. And in the actual production, cone crushing machine generally used in mineral processing filed and the impact crushing machine usually used in building material and constructional engineering.

Impact crusher has better particle shape and its finished products has less ages and corners but has more powder. While the stone cone crusher machine has less powder in its finished products.

The cone crusher machine need higher cost than the impact crusher in the early stage but the spare parts of cone crusher has longer service life, which avoids frequent wear parts replacement. While the impact crusher machine needs high maintenance cost because its wear parts need to be replace frequently. So in the long run,

cone crusher machine is more cost efficient than the impact crusher machine. To sum up, impact crushing machine and cone crushing machine both have advantages and disadvantages. And you should select crushers according to the actual production conditions, such as material hardness, capacity, capital etc. Leave your production demands, we will provide you professional solutions.

*We will provide you with the most suitble producets*

*Wo Promise to reply within 24 hours.*