The influencing factors of the ball mill working efficiency include the amount of water added, grinding balls, raw material formula, current, dispersant, reducer, etc. The combined effect of these factors ultimately determines the ball mill's working efficiency. Therefore, the improvement of ball mill working efficiency has to improve from the above six aspects.

The water content of the processed material will affect the working efficiency of the ball mill. Therefore, it is appropriate to add moisture to the raw material to prevent the ball mill from processing too dry raw materials, which can also play a significant role in improving the efficiency of the ball mill.

The diameter of the grinding balls is one of the factors affecting the efficiency of the ball mill. Different ball diameters of the ball mill are more favorable for the grinding, which can improve the working efficiency of the ball mill.

There is no certain standard for the raw material formula of the ball mill, or the standard of the raw material formula is suitable for the actual working conditions, so that the ball strength of the ball mill can be improved and its weight and inertia can be increased to help the ball mill to a certain extent Work efficiency.

The current of the ball mill is equal to the energy input of the ball mill. Increasing the current of the ball mill will increase the speed, which will directly improve the working efficiency of the ball mill. There is a certain range for the current increase of the ball mill. The upper limit of the current increase is that the power of the ball mill reaches the rated power range. Once it exceeds, it will burn the ball mill.

Properly adding a dispersant to the ball mill during work is also conducive to improving its work efficiency. In fact, in the normal production process, operators are better able to find and solve problems. Not only that, operators can also innovate and improve on the basis of the actual personal experience.

The speed of the ball mill has a great impact on the grinding efficiency of the mill. Increasing the speed of the ball mill can directly improve the working efficiency. Therefore, installing a speed adjustment device to appropriately improve the speed of the ball mill can improve the efficiency. In addition, installing a frequency converter also has a similar effect.

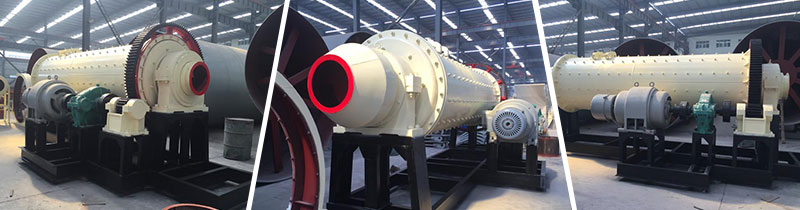

China First Engineering Technology Co,Ltd. (CFTC) company focuses on details and standards in ball mill production and has high requirements, and strict supervision on production. From raw materials to the factory to product molding, CFTC is strictly in accordance with international production standards and market demand standards, and our products are sold throughout the country and exported to Europe, the United States, Asia and other international market and won a good reputation.

*We will provide you with the most suitble producets*

*Wo Promise to reply within 24 hours.*